Get in touch to start a productive collaboration

clic and fill in the form

or send an email to: uff.tecnico@kriladesign.com

Here are all thermoplastic materials we handle and process:

- Pmma (polymethyl methacrylate)

- Shockproof Pmma (shockproof polymethylmethacrylate)

- Ps crystal (polystyrene)

- Anti-shock ps (shock-resistant polystyrene)

- San (styrene-acrylonitrile, copolymer)

- PC (polycarbonate)

- Pc + Abs (polycarbonate + acrylonitrile-butadiene-styrene, copolymer)

- Abs (acrylonitrile-butadiene-styrene copolymer)

- Pa6 (polyamide from caprolactam)

- Pa6 30% fv (polyamide from caprolactam + fiberglass)

- Pa6 St2 (polyamide from caprolactam + rubber)

- Pa66 polyamide from hexamethylenediamine-adipic acid)

- Pa12 (dodecanoic acid polyamide)

- Pom (polyoxymethylene)

- TPV Santoprene (thermoplastic elastomer based on cross-linked rubber)

- PVC (polyvinyl chloride)

- PP (polypropylene)

- PE (polyethylene)

Here are the services offered to our clients:

- Industrial design

- Feasibility analysis

- Design

- Industrialization

- Selection of thermoplastic materials suitable for the configuration of the item and its intended use

- Mechanical processing

- Rapid prototyping

- High quality injection molding

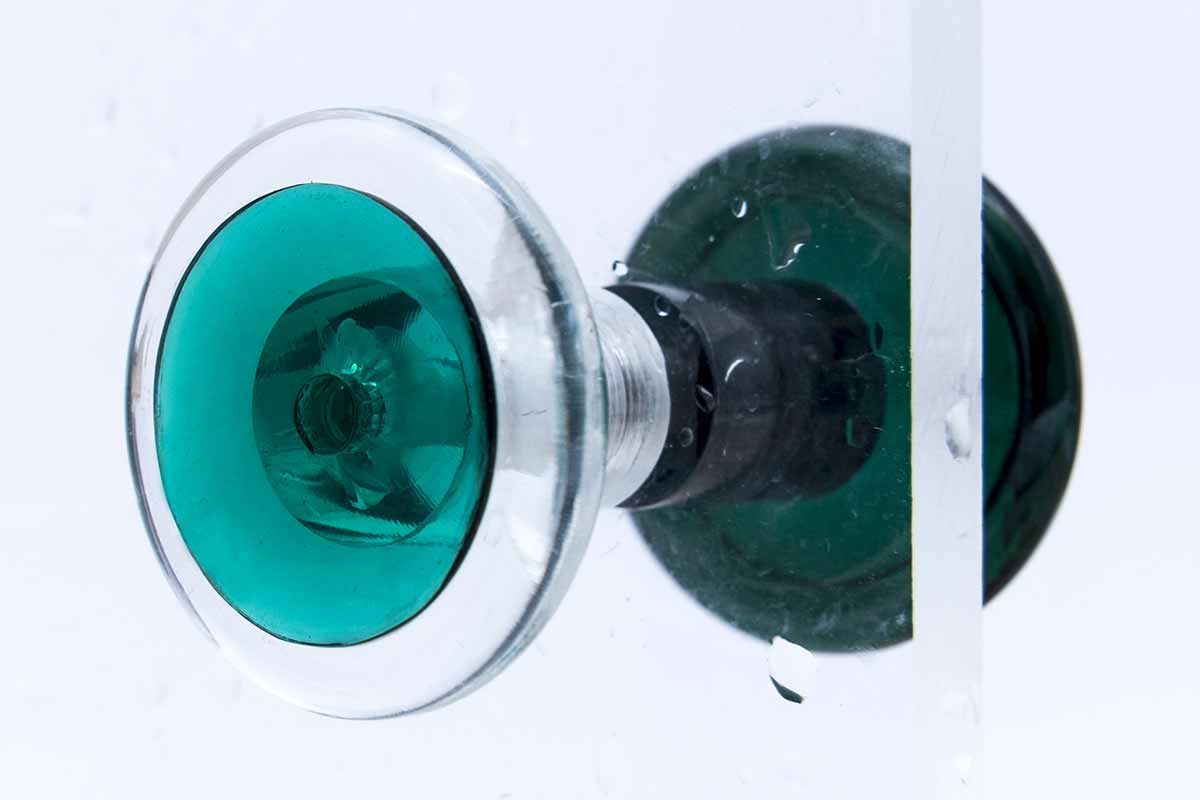

- PMMA methacrylate molding in large thicknesses

- Production of molds and specific equipment (molds for auxiliary workings, etc.)

- Evaluation of productivity and life cycle of the molds, related to the expected production volumes

- Assembly and packaging

These materials are ideal to let the design creativity spread free, while ensuring the best functionality and performance. We can turn them into any possible shape, surface and effect: glossy, opaque, transparent, satin, sanded, crystal effect, neutral or colored. We also provide the hygiene and non-toxicity certification.