Before being a brand of LED lighting for indoor and outdoor spaces, Kriladesign starts as a company specialized in injection molding and the processing of thermoplastic materials, third parties. With 45 years of history and experience behind us, we are constantly committed to turning ideas and projects into high-quality tangible products, partnering as a creative and manufacturing collaborator with various companies, at both regional and national levels.

Injection molding is a fundamental technology in modern manufacturing, providing a revolutionary method for producing plastic parts with the highest precision. And in order to ensure product reproducibility, it also offers flexibility in material selection and finishes, making it essential to meet the design and functionality needs, demanded by the market and production sectors.

Our work: what does it involve?

The Molding Division team guides clients through every phase of the production process, optimizing it to reach quality, efficiency and cost-effectiveness:

- Industrial Design and Feasibility analysis. We work closely with clients to transform their ideas into feasible projects, carefully assessing the technical and commercial viability of each proposal.

- Design and Industrialization. Through advanced software, we develop detailed projects, optimizing every component for production while ensuring efficiency and quality.

- Selection of Thermoplastic Materials. Our in-depth knowledge of materials allows us to choose the most suitable ones for specific requirements of each project, ensuring optimal performance and durability.

- Mechanical Processing and rapid prototyping. With precision machining and rapid prototyping services, we let clients visualize and test their products before launching full-scale production.

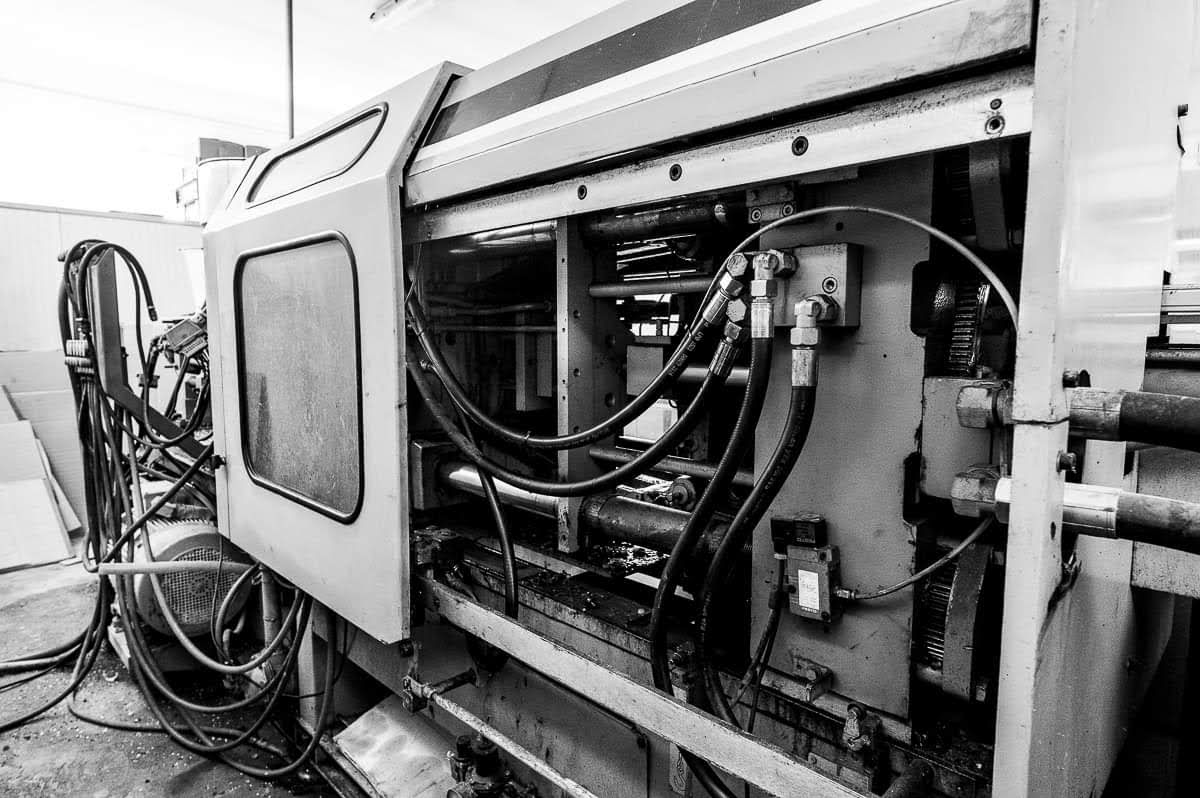

- High-quality injection molding. We have state-of-the-art equipment for molding complex components, ensuring excellent finishes and tight tolerances.

- Production of molds and specific equipment. We design and manufacture custom molds and auxiliary equipment, ensuring every aspect of the production process is optimized to meet client needs.

Research goes on and on, same our commitment to sustainability

Our goal is to strengthen and continually expand our know-how, always taking a step forward and refining the solutions we provide. That’s why we invest in research and development, exploring new combinations of materials and technologies (such as integrating methacrylate and LED light). In our work, we strive to make choices respecting nature and minimize our environmental impact. We believe in the value of a circular economy and therefore identify appropriate solutions for using recycled materials, obtained from internal production scraps, to create new products.

First, Trust.

Companies trusting us, some for many years, belong to various industries, To name some: bathroom furnishings, furniture, toys, healthcare, coffee machines, doors and windows, footwear, lighting, automotive, and more.

We collaborate with leading companies in our region, such as:

- Clementoni Spa, Recanati (we serv for components for toys),

- Simonelli Group Spa, Belforte del Chienti (accessories for coffee machines),

- Garofoli Spa, Recanati (MC) (components and accessories for doors and windows),

- Soema Srl, Recanati (MC) (locker room furnishings for gyms, swimming pools, highway rest stops, hotels, and airports).

Beyond regional borders, we work with Rephase and Vivipharma Spa in Galazzano (RSM), producing containers for dermocosmetic products.

Our artisan soul.

In our workshop, the passion for craftsmanship remains alive and coexists with technology and process innovation. Our company is made up of people following every phase of the production process with care and dedication, putting human value at the center of each project.

While we may not offer large-scale production or sky-high numbers, we do guarantee quality craftsmanship, direct customer relationships and the power to customize every project to meet specific needs.

Working side by side as partner allows us to transform ideas into unique and tailor-made products. This "personal" approach makes the difference, strengthening mutual trust and fostering open communication. Being a craft-based laboratory that also leverages new technologies enables us to always find solutions to the challenges presented to us and to successfully bring projects to completion.

Quality comes from attention to detail, passion for our work and the drive for upgrading and improvement. We are proud to put our best efforts at the service of our clients, supporting them in problem-solving, turning their projects into solutions and fostering to the success of their products and business.

Looking for the right partner for your company? Contact us and together we will bring your future projects to life!